As with most things wine, the proliferation of wine barrels began with the Romans. And, as with most things Roman, wooden barrels were an idea stolen from someone they conquered.

Roman author and naturalist Pliny the Elder (you might know him from the beer) encountered craftsman making wooden barrels when he visited the Celtic civilization of Gaul during the first century AD. These watertight vessels were made from oak and fastened with metal rings. At the time, they were designed to hold water, oils and were sometimes used as makeshift explosives used in combat. The Romans were interested in these barrels mainly because they would aid the transportation of wine throughout the empire. By this time, wine was already being traded throughout Rome, but in amphorae – handled clay vases similar in size to today’s wine bottles. With the adoption of wooden barrels, Romans quickly discovered that they could move more quantities of wine in lighter, stronger, containers, which were easy to roll for overland transportation to all those conquering troops Rome needed to take over the world.

Today, barrels are rarely used to move wine. Now, wine is typically transported across long distances either in the bottle or in large plastic bladders. Instead, barrels have become the preferred method of wine storage, and play a significant role in actually forming the identity of wine as we know it today. They’re appreciated for their interaction with the wine and their ability to help in the aromatic and structural makeup of a wine. In other words, they just make wine taste better.

The Wood

To be fair, ancient Mesopotamian civilizations were using palm wood to create barrels for wine, but this type of wood was tough to bend, so the tradition didn’t last. Oak, on the other hand, was found to be much more pliable and easier to work with.

Today, there are literally hundreds of species of oak in the world, and they fall into two types: red and white. Red oak tends to be porous and therefore doesn’t hold liquids well, whereas white oak is tighter and is ideal for holding wine and other liquids. That’s why white oak is harvested throughout North America and Europe for the purpose of barrel crafting in the modern world.

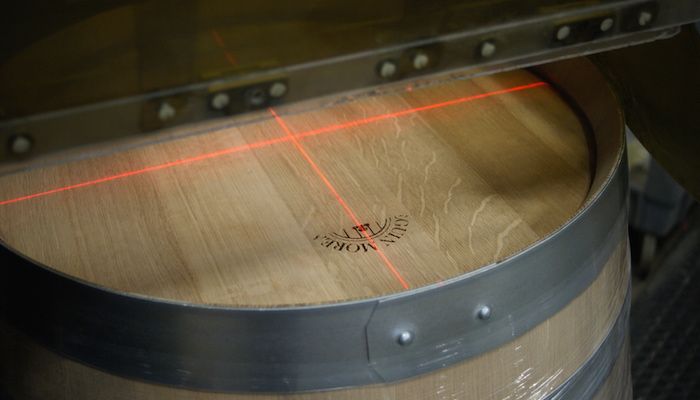

So how does that oak go from tree to barrel? We went to a premier cooperage in Napa to find out. Seguin Moreau, which traces its roots back to 1838 France, is a leader in modern wood and wine research. Though their process is intricate, cooperages like Seguin Moreau tend to stick to traditional methods that have been around for generations.

It all starts with the trees. With some of the bigger cooperages making upwards of 75,000 barrels every year, it shouldn’t be a surprise that hundreds of thousands of oak trees around the world are cut down annually to help support the wine industry. One tree can only make about two to five barrels, depending on the process of cutting the staves.

In France, barrel-oak forests are run by the ONF, the country’s national forestry office. Government-run forests have been in operation in France for over 400 years and were first maintained in order to produce wood for an immense naval fleet. Today, used solely for wine barrels, these forests are, by nature of the business, sustainable and carefully maintained. Only about 10 percent of the oak tree saplings that grow in a forest are actually allowed to grow into full maturity. Many are uprooted to allow only the very strongest to survive. Having fewer trees in the forest means eliminating competition and oak trees grow tall and straight without much branching.

In the United States – as you might have expected – the oak tree business for wine barrels is not government run. Imagine that bill trying to pass the Senate. Instead, growers of oak trees for wine barrels are private landowners, and occasionally cooperages will grow their own trees. Oak tree growth in America isn’t nearly as regulated as it is in France, but the native oak on this continent doesn’t need as much tending as its European cousin. It is naturally stronger than French oak, which makes the harvesting and sawing process quicker, easier and less expensive.

Though French and American are the most well-known oak used for barrels, trees from Hungary, Russia, Croatia, Portugal and other European countries are also used. And the average age of a tree used for barrels is 160, which means it’s a multi-generational pursuit, no matter where you are in the world.

How Barrels are Made

Once the trees are harvested, the wood is then matured outside in the elements for two to three years. The aging process of the wood itself is a low-tech, low-energy way to dry out the wood, ridding it of its young, green aromas and using rain and snow and wind to wash away harsh tannins to prepare it for wine storage.

After maturing, the wood is cut into staves (the individual slats that make up a barrel). Staves are cut with the utmost precision so that when they are placed together they fit into a watertight seal. Then, inside the hot and noisy cooperage, the process is quick and precise. All the steps inside the cooperage are done through assembly line, and it typically takes about one hour for a barrel to go from beginning to end.

To begin, a group of staves are assembled with the bottoms forming a circle and the tops flaring out. Metal rings are placed around the rosette to help it keep its shape and prepare the barrel for bending.

The rosettes are then placed over an initial fire for 10 to 15 minutes to help bend the staves into the concave barrel shape we’re all familiar with, and additional metal rings are hammered down over the staves to keep them in place and the seal tight.

Next is toasting. A process that the French refer to as bousinage, toasting uses fire to bring out the barrel notes that will be available to the wine. Toasting mellows out harsh oaky tannins so your wine doesn’t taste like a cedar closet. It also adds aromas to the wine that wouldn’t exist otherwise – aromas like hazelnut, vanilla, black pepper and espresso. Once the barrel takes its shape and the rings are in place, it’s placed over a small fire until it turns a caramel brown – about 15 minutes, depending on the required toast level. There are various levels that cooperages make available, and typically include light, medium, medium long, medium plus and heavy. The longer the barrel sits over the fire, the more toast a barrel will get. Winemakers typically make specific requests for specific toast levels on their ordered barrels to match perfectly with their vintages.

After toasting, the barrel heads are hammered in and secured with a sticky paste made with flour and water. Then the bunghole (yes, bunghole is the official term) is cut in the center of the barrel, and it’s ready to be filled with liquid. Of course coopers don’t start with precious wine; they fill each barrel with water to test the quality of the seal. The barrels are left for about a half an hour with water in them to see if the staves spring any leaks. Occasionally a stave on a barrel will start to moisten on the outside, and this is an indication that the stave should be replaced. But, it’s an easy fix for a cooperage with pre-cut staves that can replace the leak and put it right back into the production line.

Finally, if a barrel has passed the water tightness test it’s ready to be sanded and engraved with the appropriate markings, which typically include the toast level, the year, the cooperage and the winery.

Despite its long life as a tree, the life of a barrel is short. A barrel will spend two to three years, tops, holding wine. Then it may be used to store whiskey and other spirits for a couple years, and finally, if it’s lucky, it might live forever as home decor.

Wood + Wine 4ever

Certain red and white wines are ideal to age in oak barrels. Reds tend to be aged longer – about 12 to 18 months, depending on the vintner. During this time, the barrel and its wine are constantly exchanging chemicals and particles. Ellagic tannins are critical chemical compounds diffused from a barrel into the wine. These magic little guys encourage oxidation, which helps a wine grow up from a young, in-your-face teen to a mellowed out twentysomething and eventually – once bottled – into a perfectly seasoned adult. These tannins from the barrel add to the structure of the wine that helps it stand up to the aging process, so aging wine in an oak barrel is basically the equivalent of you eating your blueberries.

And then there are the aromas: American white oak is known for having higher levels of whiskey lactone than European species of oak, which means wines aged in American oak will pick up the distinct aromas of coconut and bourbon from the barrel. Oak from France is known for its more subtle aromas because of its tighter grain.

Winemakers decide which barrels they prefer – American or French – and which toast level best suits the needs of their wine. For example, Napa’s famous cabernet sauvignon is often barrel aged in American oak for its New-World coconut and bourbon aromas and toasted to medium or medium plus for the vanilla aromas. The choice of oak and toast level are extremely specific and personal. It relies entirely on the qualities a winemaker wants to impart on his or her wine.

The Future of Barrels

The future of barrel making for wine is unknown. Cooperages are now experimenting with specially engineered oak chips to give wine oak characteristics without the barrel aging, while some winemakers are trying their luck with even more ancient storage techniques. The oak wine barrel is still hand-crafted using much of the same techniques used almost two thousand years ago, and from a completely natural resource no less.

The barrel is undoubtedly part of the romantic allure of wine, and it has such a significant impact on the wine itself. It’s hard to imagine the wine industry without it. But as science digs deeper into how wood interacts with wine, perhaps the door is open for creating those interactions in other ways.

Images courtesy of Seguin Moreau Cooperage